Overview

September 2014 - March 2015

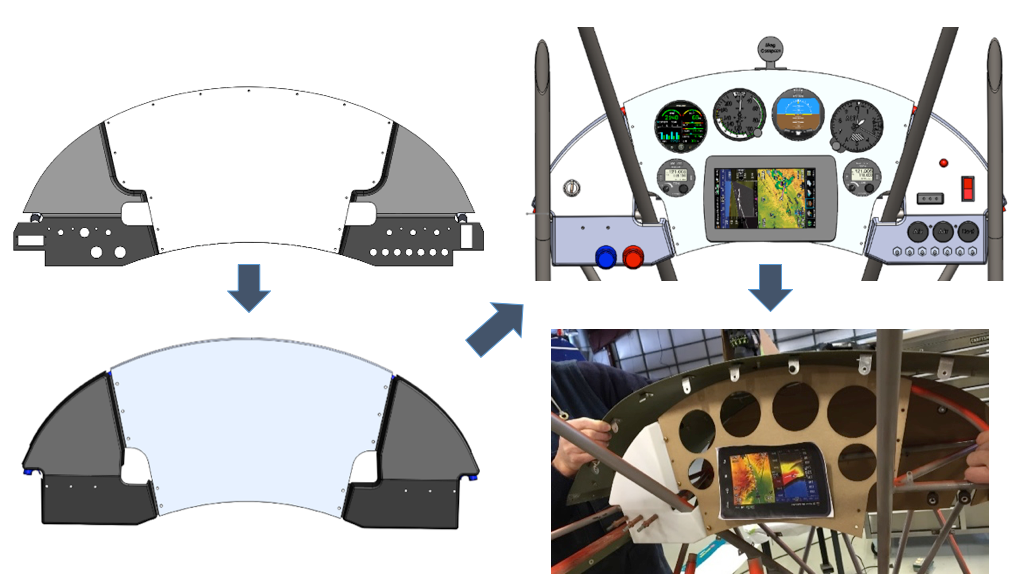

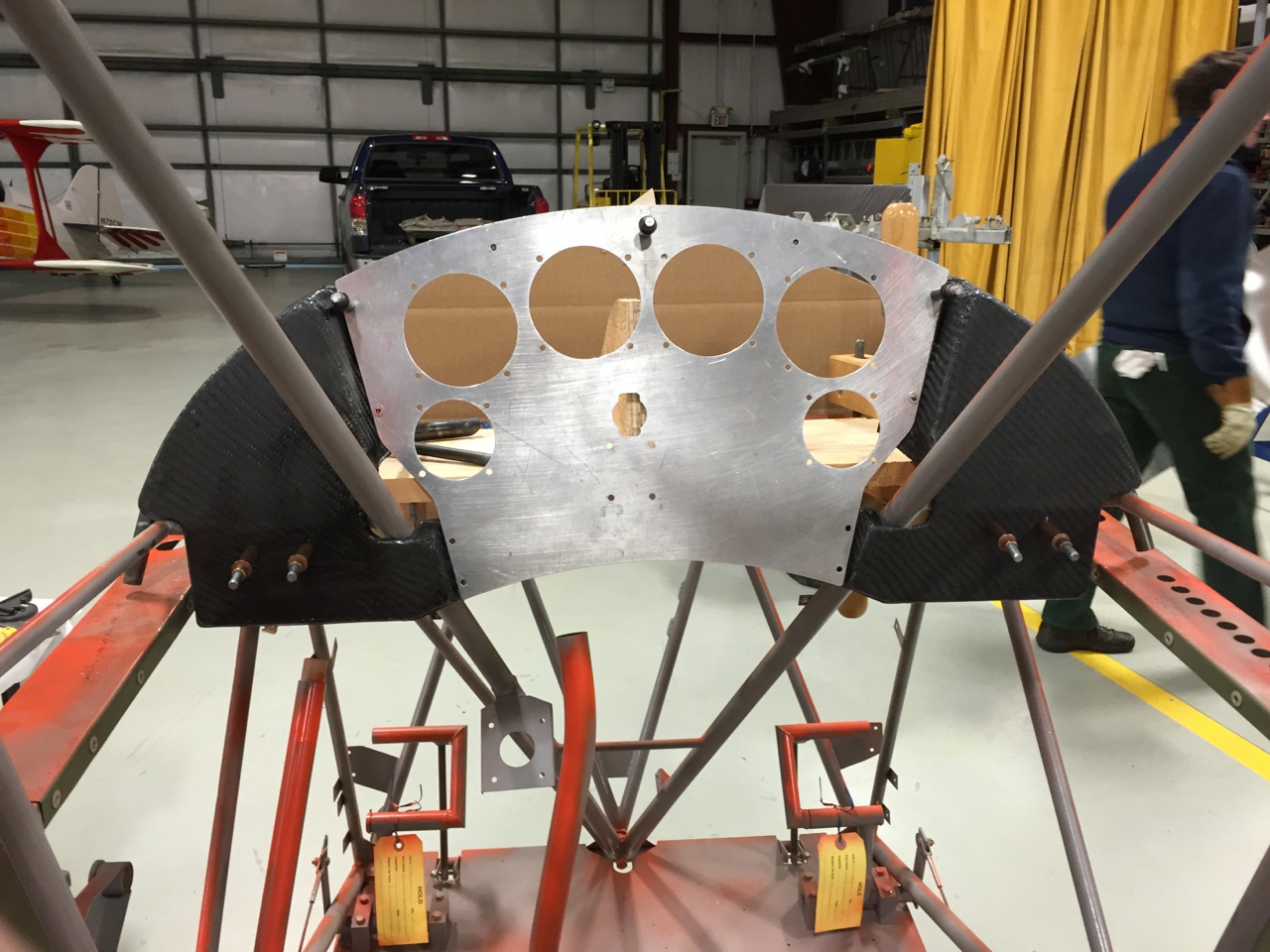

For my senior capstone project I served as technical lead on a team of 5. We were tasked with redesigning the instrument panel and rear seat of the Arctic Tern with the objectives of improving user comfort, modernizing the interior, and reducing weight. In a 20 week period, we design, built, and tested a carbon fiber instrument panel and carbon fiber rear seat. In total, we saved ~25 lbs and ensured our deliverables conformed with FAR Part 23 regulations.

Achieved

- Net weigh reduction: 13.5 lbs (Final weight 18.7 lbs)

- Increased control stick clearance: 1.5 in.

- Added glare shield and recessed center panel improved visibility.

- Pass. Held 150% ultimate load of 210 lbf for over 1 minute.

Specifications and Requirements

Net Weight Reduction Target: 10 -15 lb

Increase control stick clearance: 1.5 - 4.0 in

Address glare issue

Static Load Requirement ( +4.4G * 1.5 SF ): 210 lbf

Before

After

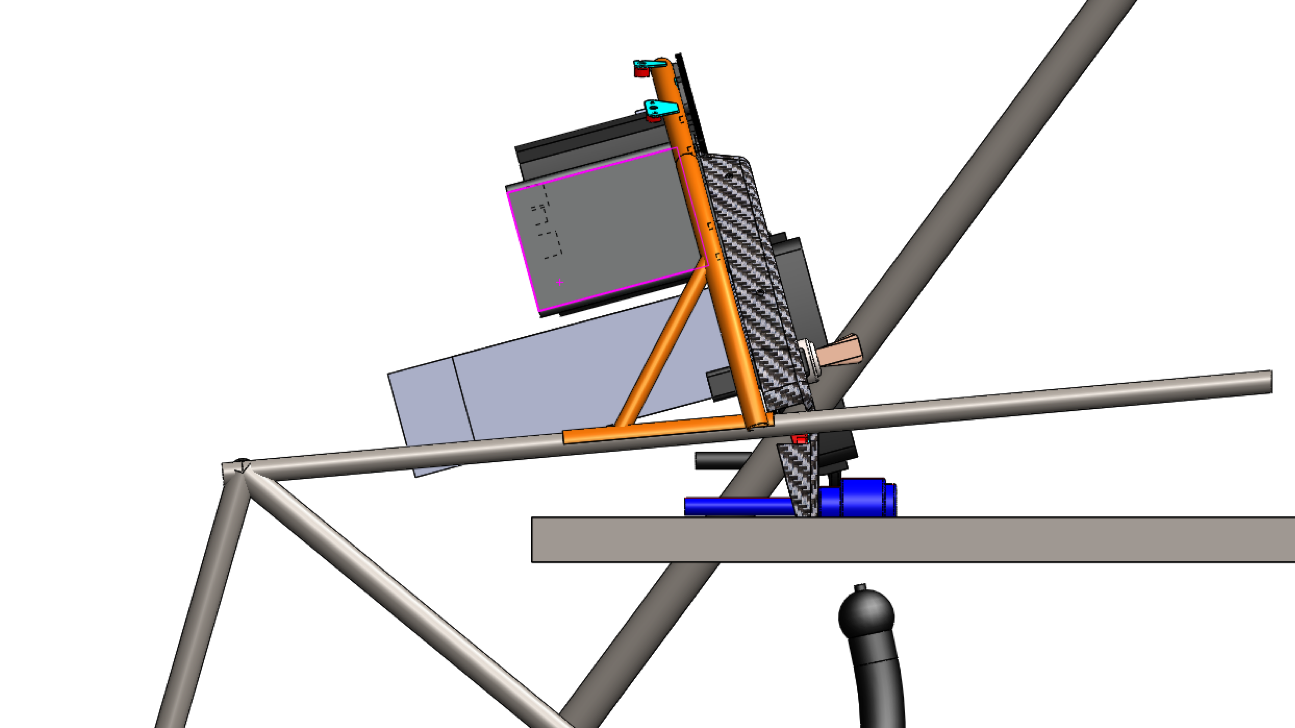

Design

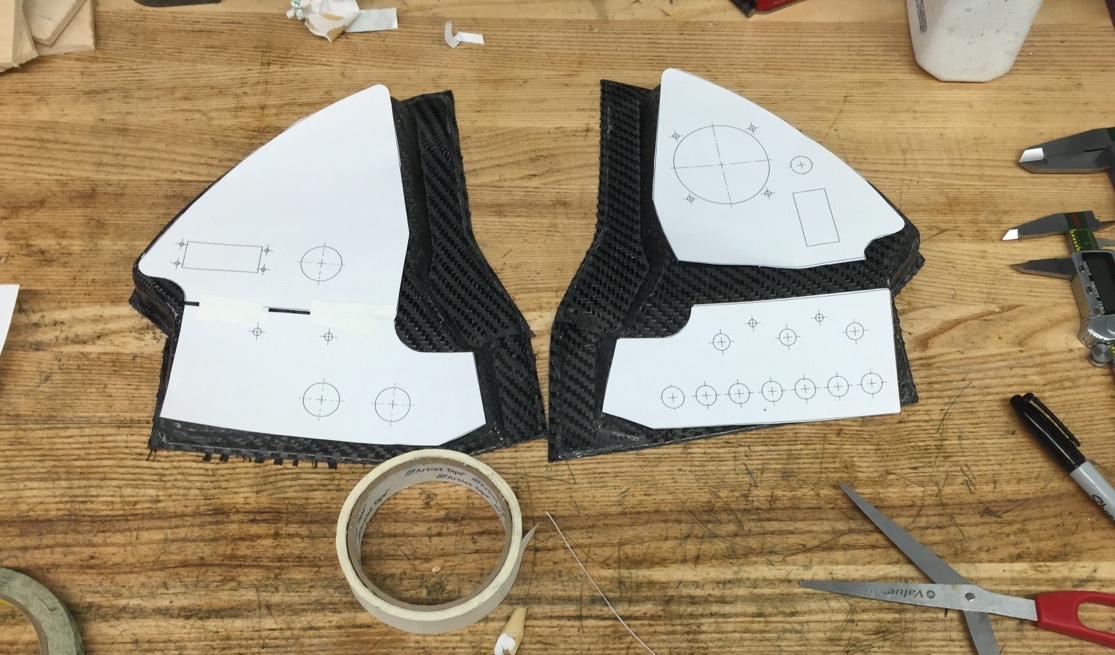

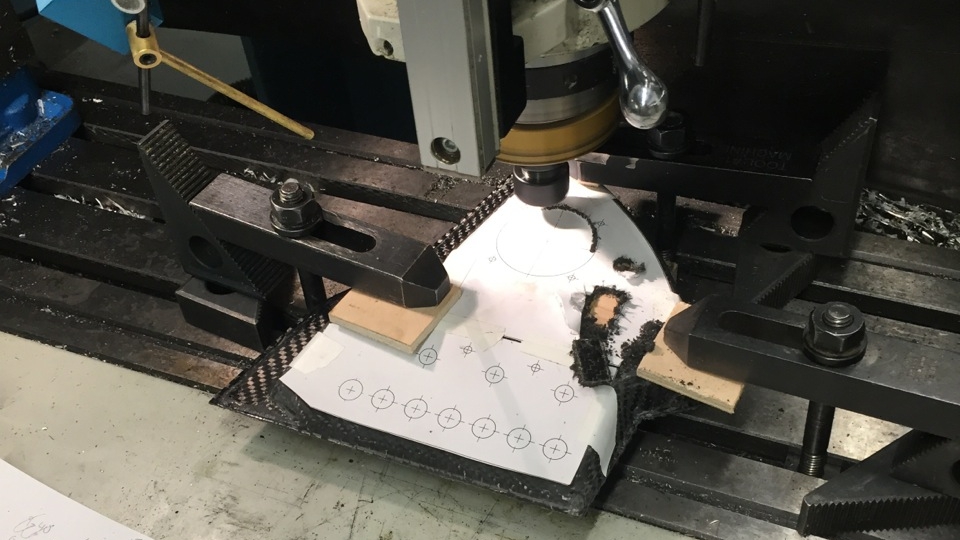

Build

Test

My Contributions:

- Selection of instruments.

- All instrument panel CAD, CAM, and CNC fabrication.

- Mold construction.

- Composite fabrication of panel

- Performed static load testing.